The Rotary Cup Burner ・2012年3月27日

The Core Technology of Every Sunflame Product

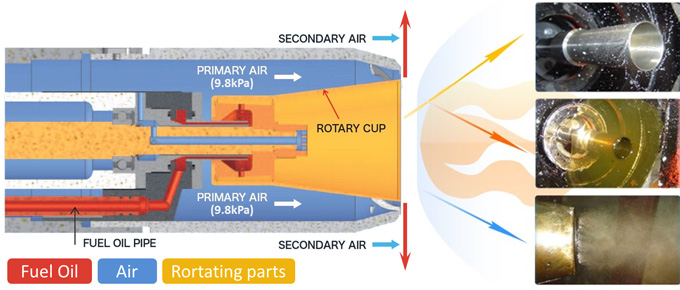

Structure of Rotary Cup Burner

The rotary cup burner forms a film of fuel oil by the centrifugal power of the cup rotation. By giving high air pressure to this film spread fuel, the rotary cup burner creates very fine oil mist which is necessary for good combustion.

The Advantages of the Rotary Cup Burner

| Atomization | Oil Pressure | Fuel Viscosity | |

|---|---|---|---|

| Rotary Cup Burner | Atomization by the centrifugal power with high air pressure |

Low pressure 3-5kg/cm2G |

Wide range of viscosity |

| Pressure Jet Burner | Atomization by oil pressure |

High Pressure 20kg/cm2 |

Limited range of viscosity |

The most dominant characteristic of the rotary cup burner is the way of its atomization.

Unlike the pressure jet burner which needs a small nozzle for atomizing, the rotary cup burner uses a cup with wider holes, meaning the structure of the rotary cup burner secures the burner from choking. By this characteristic, the rotary cup burner is capable of firing high viscosity oil like the HFO.

Moreover, the rotary cup burner utilizes the centrifugal power for atomizing, which means that high pressure is needless for atomization. The low oil pressure of the rotary cup burner is safer to use when there is any leakage from the piping.